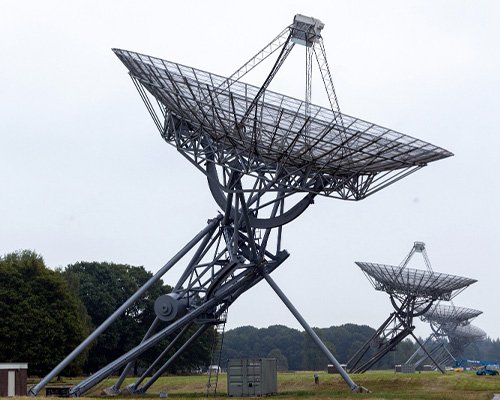

Wireless

Telecommunication

Machine

automobile

AEROSPACE

PDC PARTS

SURLON PRECISION SOLUTIONS INDIA LIMITED

HIGH PRECISION WIRELESS & TELCOMMUNICATION PARTS

HIGH PRECISION MACHINE PARTS

AUTOMOBILE PARTS

AERO SPACE PARTS

Any manufacturing process,

any component, any size

Process – Production & Tooling

High Pressure Die Casting (HPDC), Low Pressure Die Casting (LPDC), investment casting, sand and gravity casting, metal injection molding, precision machining, aluminum alloy extrusion, forging, metal stamping, sheet metal fabrication, steel fabrication, plastic injection molding and thermoplastic tooling, molded rubber and elastomers, composites, electronic PCB assemblies, and more.

Finished Parts – Full Range of Services

Secondary operations include CNC machining, drilling, tapping, and reaming; part surface cleaning; heat treatment; surface finishes such as plating, polishing, painting, powder coating, wet spray, and E-coat; along with graphics, hard coating, testing, assembly, and packaging.

PRECISION CAPABILITIES

End-to-end metal fabrication for enclosures, cabinets, and racks, offering heavy and medium-duty automotive chassis and frame fabrication, along with high-precision light fabrication for robotic chassis.

Precision aluminium extrusion solutions for heat sinks, EV charger body frames, and specialized profiles for architectural, industrial, and automotive chassis, frames, and custom applications.

High-quality die cast components for pump, motor, and sensor housings, along with ornamental, decorative, and diverse automotive and industrial applications.

High-quality forged components including gears, sprockets, shafts, and camshafts, serving high-volume automotive and industrial requirements.

Precision sheet metal stamping for custom components, utilizing coiled or blanked sheet metal and supporting both short-run and high-volume production with bending, cutting, and welding operations.

Advanced Metal Injection Molding for high-precision components, from a few grams to multi-kilogram parts.